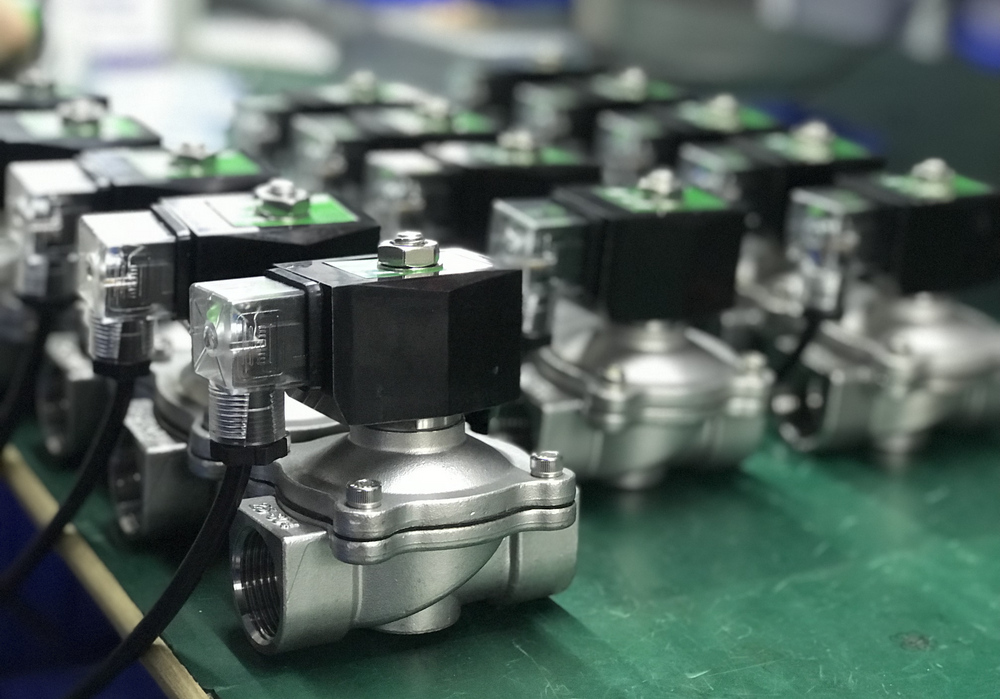

Solenoid Valve is the most used one of the automatic valves, because it is efficient, easy to use, and the price is also relatively low. Solenoid valve consists of coil and core, coil power or power off to control the operation of the core, thus changing the direction of the fluid. Solenoid valve components are relatively simple, by fixed iron core, moving iron core, coil components; valve body part by spool, slide valve sleeve, spring base, etc.

The most commonly used are stainless steel solenoid valves, brass solenoid valves, two position-three way, two position-five way, and so on. In this case, the two position and three position valves refer to the different working positions of the valve cores, while the two way and three way valves refer to two or three different interfaces on the valve body of the reversing valve. Different pipes can only be connected by the valve port switch when the valve core is shifted.

Solenoid Valve in the daily operation of the process will also have some faults, these faults will directly affect the use of valves, common faults are solenoid valve not to act, to check and solve from the following aspects:

1. The solenoid valve terminal is loose or the wire head is disconnected, which will cause the solenoid valve to not be powered and cannot be used. This kind of problem is very common. We can tighten the wire head or check it before use.

2. Water in the solenoid valve, overload or unstable voltage will cause the solenoid valve coil to burn out. In this case, we can remove the solenoid valve wiring and measure it with a multimeter. If the circuit is open, the solenoid valve coil will burn out. In addition, the spring is too hard, the reaction force is too large, the number of coil turns is too small, and the suction force is not enough to cause the coil to burn out. During emergency processing, the manual button on the coil can be turned from the “0” position to the “1” position during normal operation to make the valve open.

3. The gap between the valve sleeve and the valve core of the solenoid valve is very small, and many are assembled by one piece. If the lubricant is too little or there are impurities entering, it will cause the valve to freeze. We can disassemble the solenoid valve, take out the valve core and the valve core sleeve, and then clean it with cci4, so that the valve core can move flexibly in the valve sleeve. When disassembling the valve, pay attention to the assembly order of each component, so that it can be reassembled and wired correctly. Also check whether the injection hole of the oil mister is blocked and whether the lubricant is sufficient.

4. There are also many problems with the leakage of the solenoid valve. Leakage will cause insufficient air pressure inside the valve, cause difficult opening and closing of the valve, damage to the sealing gasket or wear of the slide valve, resulting in blow-by of several cavities. When dealing with the malfunction of the solenoid valve of the switching system, you should choose a suitable time and wait for the solenoid valve to be dealt with when it is out of power.

PDF Get-a-Product Catalogue