▋ Introduction

Refer to IOM to get Brass Solenoid Valve 12V Design, Diagram, Symbol, Dimension, Parts, Weight, Assembly & Installation Instructions.

Brass Solenoid Valve 12V Price: Contact us

▋ Process Flow

▋ Finished Project

▋ About COVNA

Features

Refer to IOM to get Brass Solenoid Valve 12V Design, Diagram, Symbol, Dimension, Parts, Weight, Assembly & Installation Instructions.

Brass Solenoid Valve 12V Price: Contact us

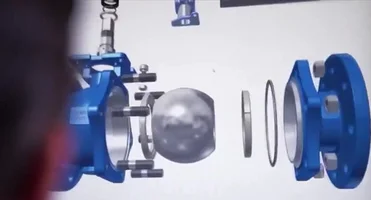

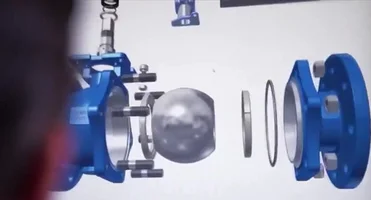

| Size Range | 1" to 4" |

|---|---|

| Pressure Range | 0.03MPa to 1.6MPa |

| Switching Function | Normally Closed (NC) |

| End Connection | Flanged |

| Body Material | Brass |

| Sealing Material | NBR, EPDM, VITON (FKM), PTFE (TEFLON) |

It is normally closed. When there is no power to the valve, it is in the closed position.

The valve has a 100% duty cycle and is rated for continuous duty. It can be in the open position, with power applied, all the time without problems.

No. Particulate matter can prevent the piston from completely closing the valve – causing leakage.

There is none and none is needed. The outside temperature of the coil can reach 180F in normal operation and will cause no damage to the valve.

Fluid inside the valve can reach temperatures above ambient because of the operating temperature of the coil. The hot coil heats the process media which can raise its temperature considerably. Remember, the fluids that may not affect the valve seals at ambient temperature can cause problems at higher temperatures.

The valve opens and closes almost instantaneously.

As the flow velocity increases so does the potential for generating damaging shock pressures as the valve opens and closes. At flow velocities above 5 feet per second, this shock pressure can be great enough to damage the valve, especially the diaphragm seals.

If the inlet pressure is greater than 25 PSI, and the pressure differential (the difference between the inlet and outlet pressures) must be GREATER than 25 PSI of the valve to open and close smoothly. You can test it by operating the valve without pressure or flow going through it to verify that that is the cause.

Same answer as the last question.

The valve itself can withstand 150 PSI without damage, but the coil and spring that open and close the valve won’t work above 120 PSI.