▋ Introduction

Custom Double Acting Pneumatic Valve with double acting pneumatic actuator. Pre drilled metric ISO5211 direct mounting pad to minimise any thermal transfer from valve to actuator. Anodized aluminium rack and pinion actuator with visual indicator, namur interface and stop adjustments. Typical applications include water treatment, chemical, marine, petrochemical and general industry.

Refer to IOM to get Double Acting Pneumatic Valve Design, Symbol, Dimension, Parts, Weight, Assembly & Installation Instructions.

Double Acting Pneumatic Valve Price: Contact us

▋ Characteristics

High Tensile Spring Sets

High tensile epoxy coated spring sets provide high performance in fail safe and emergency shut down operations.

NAMUR Mounting

Direct mounted solenoid connections according to NAMUR standards.

ISO 5211 Bottom Mounting Connection

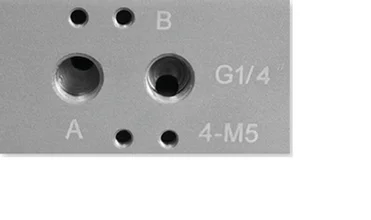

Base drilling, for valve mounting, and centering, according to ISO 5211/DIN 3337 standards.

High Visibility Position Indicator

The indicator is to remain on the actuator for continuous indication when limit switch is not being used.

▋ Working Principle of Single Acting (Spring Return) Pneumatic Actuator

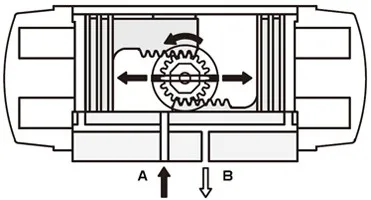

CCW

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

CW

Air to port B forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

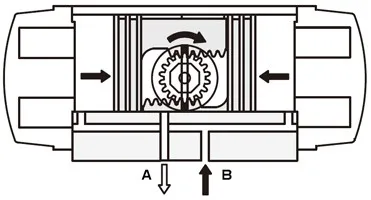

▋ Working Principle of Double Acting Pneumatic Actuator

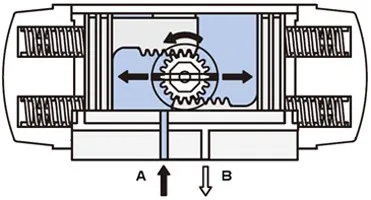

CCW

Air to Port A forces the pistons outwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port A.

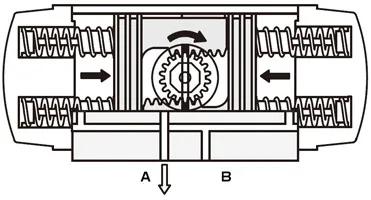

CW

Air to Port A forces the pistons outwards, causing the pinion to turn clockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port A.

▋ Process Flow

CNC Sawing

Sawing with accuracy and precision.

CNC Machining

Advanced CNC machine from German.

Lasering

Lasering production batch and model info.

Semi-finished Products

Partly finished actuators and components.

Actuator Assembly

Manufactured by qualified engineers.

Final Quality Control

All are 100% tested before shipping.

▋ Finished Project

▋ About COVNA

COVNA – Solve your technical questions with solid experience

We are COVNA Automations, one of the top manufacturers of quarter turn actuators and actuated valve products in Dongguan, China with 18 years experience. Our industrial experience will be useful in your business and projects.

18 Years Operation

Good credit rating. Large quantities of regular clients.

German Imported CNC Machine

Advanced CNC machine, engineer with high accuracy.

ISO 9001 Certificated

With additional certifications that include TUV SGS RoHS.

Affordable Prices

Our prices are both fair and affordable for all people.

Qualified Engineers

Designed and manufactured by experienced engineers.

Well-trained Staffs

Always available to answer your technical questions.

ODM Services

Granted you free access to download 2D & 3D models.

Standardization Production

Assure you of stable product quality and supply capacity.

Same-day Shipping

Always keep a large stock of pneumatic actuated valves.

Field Service

Provide continuous assistance in more than 40 countries.

One Year Warranty, Life Service

A period of twelve (12) months from the shipment date.

Global Presence

Find us at the exhibition or contact local representatives.