What Is Motorized Gate Valve?

Motorized Gate Valve is also called electric gate valve/motorized actuator gate valve,is an ordinary gate valve that operated by an Motorized actuator.

This means that you can open or close the valve remotely and no need to manually operated it.Save your time and keep you safe. Widely used for various applications like a power plant, shipyard, oil and gas, wastewater treatment, paper and pulp,etc.

How do Motorized Gate Valve work?

An electric motor is mounted on the valve and geared to the valve stem so that when the motor operates the valve will open or close.

Motor operated with actuator control from local panel or, from control room is required.

Features Of Multi-Turn Motorized Actuator Gate Valve:

- A one-stop valve solution for start and stop the flow rate

- Weather-proof aluminum alloy multi-turn actuator for outdoor uses

- Multi-turn actuator to help to control locally or remotely

- Offering multiple options of Fieldbus to help to connect with your control system with a right Fieldbus

- Available in WCB and stainless steel valve material for your choice

Types Of COVNA Motorized Gate Valve:

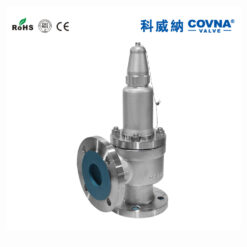

Motorized Flanged Gate Valve

Motorized Knife Gate Valve

Technical Parameter Of Multi-Turn Motorized Gate Valve Actuator:

| Model | Torque(Nm) | Maximum diameter of the valve stem(mm) | Manual Ratio | Output Rotation Speed(r/min) | Motor Power(KW) | Current(A) | Refer Weight(kg) |

| Z5 | 50 | 28 | 1:1 | 12/36 | 0.12/0.18 | 0.57/0.83 | 28 |

| Z10 | 100 | 28 | 1:1 | 18/36 | 0.25/0.37 | 1.03/1.38 | 45 |

| Z15 | 150 | 28 | 1:1 | 18/36 | 0.37/0.55 | 1.38/2.2 | 46 |

| Z20 | 200 | 40 | 1:1 | 18/36 | 0.37/0.75 | 1.38/2.62 | 56 |

| Z30 | 300 | 40 | 1:1 | 18/36 | 0.55/1.1 | 2.2/4 | 58 |

| Z45 | 450 | 48 | 1:1/20:1 | 24/36 | 1.1/1.5 | 4/4.12 | 110 |

| Z60 | 600 | 48 | 1:1/20:1 | 24/36 | 1.5/2.2 | 4.12/5.25 | 112 |

| Z90 | 900 | 60 | 1:1/20:1 | 24/36 | 2.2/3 | 5.25/7.9 | 140 |

| Z120 | 1200 | 60 | 1:1/20:1 | 24/36 | 3/4 | 7.9/8.87 | 142 |

| Z180 | 1800 | 70 | 22.5:1 | 18/36 | 4/7.5 | 8.87/15.6 | 250 |

| Z250 | 2500 | 70 | 22.5:1 | 18/36 | 5.5/10 | 12.05/20.5 | 255 |

| Z350 | 3500 | 80 | 20:1 | 18/24 | 7.5/10 | 15.6/20.5 | 330 |

| Z500 | 5000 | 80 | 20:1 | 18/24 | 10/15 | 20.5/26.6 | 350 |

Note: If the user requires, we could provide the products with other rotation speed: 12/18/24/30/36/42/48/60(r/min)

▋ Applications of Motorized Gate Valves

Paper and Pulp

Since the pulp is relatively viscous, it is easy to block the valve body, so the gate valve is a good choice and will not be easily blocked. Generally, the environment of pulp mills is harsh, but the electric gate valve or electric knife gate valve can realize remote control through signal feedback, reducing labor costs and reducing the probability of human injury.

Wastewater Treatment Plant

The wastewater treatment industry is currently the most extensive industry, generally used to treat wastewater, soil, or other dirty fluids. The medium is generally corrosive. Electrically actuated gate valves and electrically actuated knife gate valves are made of quality stainless steel. They are also highly resistant to corrosion and abrasion, so they can be used with confidence.

Cement Plant

Similarly, cement is viscous, so a gate valve or knife gate valve is a good choice. Then through the drive of the electric actuator, remote control can be easily realized and the production efficiency of the cement plant can be improved.

Power Plant

The power plant environment is relatively harsh, high temperature or high pressure, and high requirements for valves. COVNA motor actuatedgate valve and motor actuatedknife gate valve are made of high-quality stainless steel, which can be used well in high temperature or high pressure environments. And remote control can be achieved through electric actuators, reducing labor costs and the probability of human injury

▋ Packaging

▋ Certification

▋ About COVNA