ZJH Series Pneumatic Diaphragm Control Ball Valve

Short Description:

Pneumatic diaphragm control valve

comprises a multiple spring zero adjustable actuator, a low flow resistance sleeve and a single seat regulation valve without a lower cover. The flow capacity increases by 1/3. It’s of low center of gravity, high vibration resistance and easy to install. The performance indexes are superior to products of the same kind. The products are widely used in automatic production control systems in industries including chemistry, petroleum, light industry, power station, and metallurgy. We will try our best to provide the high-quality and high-tech pneumatic control valve for your various project for flow control. Inquiry us to get the free valve solution!

Model

Inherent Regulation Ratio: 50:1

Nominal Pressure : 1.6 / 4.0 / 6.4 MPa

Service Temperature: -10 to 180℃

Ambient Temperature:-30 to 70℃

Air Supply Pressure : 0.14 / 0.25 / 0.40 KPa

Spring Range: 20 to 100(Basic type) / 40 to 200 / 80 to 240 KPa

Benefits Of Pneumatic Control Valve:

COVNA Pneumatic Control Valves are suitable for regulating flow rate of pipelines. Pneumatic control valve is powered by compressed air, without electricity, safe and explosion-proof. The positioner receives and feedback the control signal of the industrial automation control system to complete the adjustment of the flow and pressure of the pipeline medium. Widely used in shipbuilding, power plants, food and beverage, and so on.

Features Of ZJH Series Pneumatic Diaphragm Control Valve:

- Globe valve is driven by pneumatic control which could allow your automation more easily and help you control the medium more precise

- Available in single-seat type and sleeve type for your choice

- Precise control: Pneumatic control valves offer precise and accurate control over the flow of fluids and gases

Major Technological Performance Indexes And Testing:

| Serial No. | Technical Performance | Without Positioner | With Positioner |

| 1 | Basic Error | ≤±5% | ≤±1% |

| 2 | Return Difference | ≤3% | ≤1% |

| 3 | Dead Zone | ≤3% | ≤0.4% |

| 4 | Leakage | ZJHP Type:≤1X10-4Rated FlowZJHM Type:≤1X10-3 Rated Flow | |

| 5 | Rated Flow Coefficient | ≤±10% | |

| 6 | Inherent Flow Characteristic | Slope±30% | |

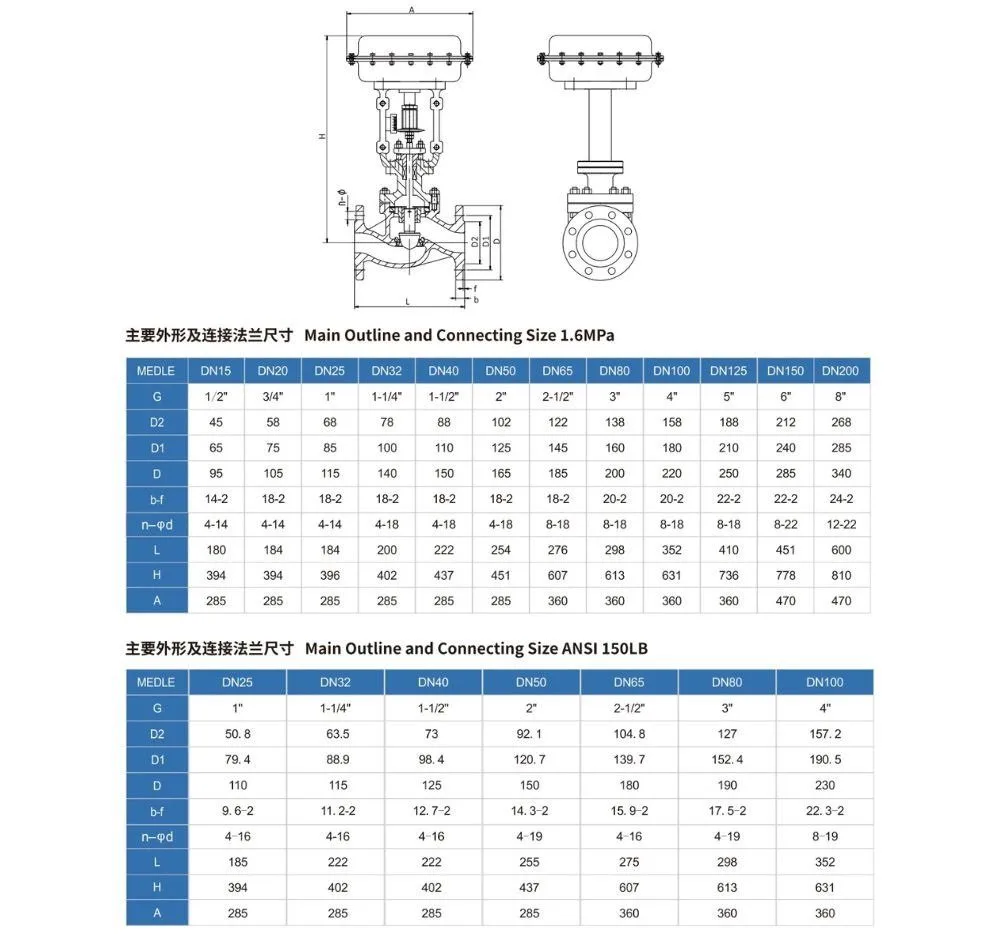

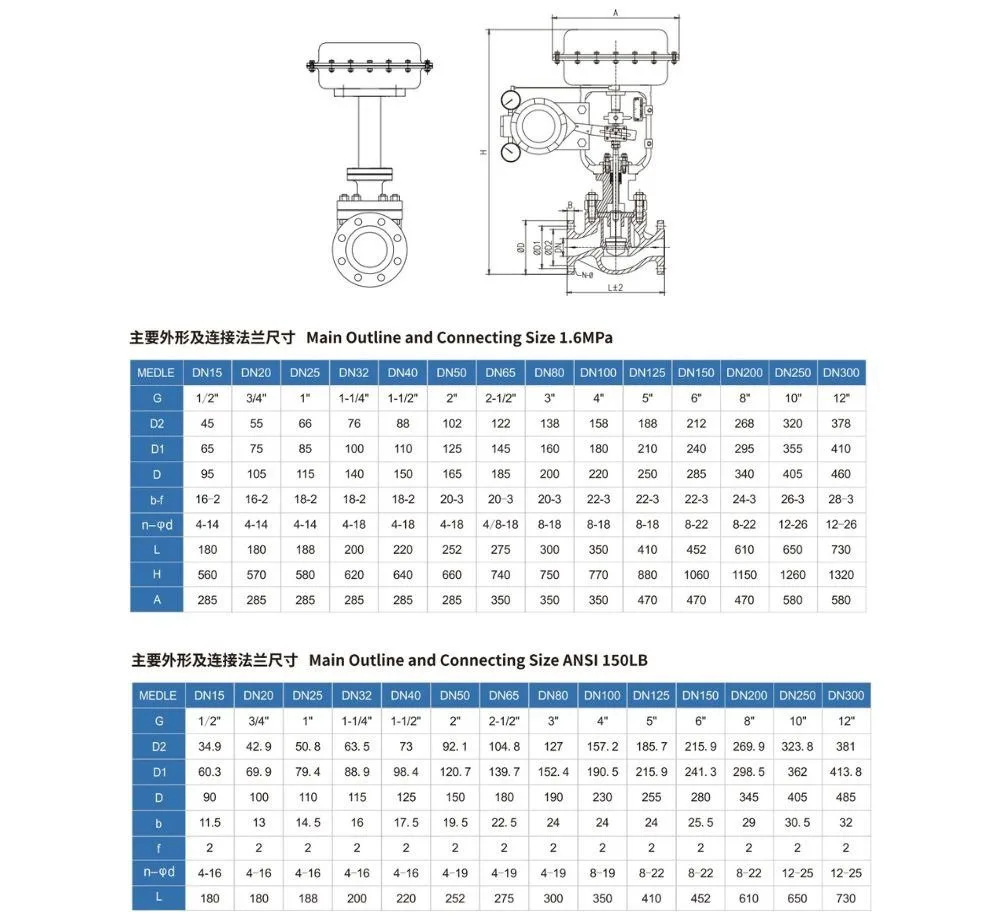

Dimension:

Applicable fields:

This pneumatic diaphragm control valve can be widely used in the following industries:

1. Chemical industry

2. Oil and gas field

3. Power industry

4. Metallurgical industry

5. Light industry automation