COVNA HKFP Anti Corrosive PTFE Solenoid Valve

HKFP Anti Corrosive PTFE Solenoid Valve

with isolated diaphragm construction to rot-proof PTFE body for corrosion resistance. Suitable for most of the corrosive mediums. Widely used in the chemical industry, cosmetics industry and so on. COVNA supplies various kinds of solenoid valves such as anti-corrosive types, water-proof types, and general-purpose types for your applications. Consult us to get the valve solution!

Model

- Function: Normally Closed

- Pressure: 0 to 1.5 bar

- Voltage: DC-12V, 24V; AC-24V, 120V, 240V/60Hz; 110V, 220V/50Hz

- Temperature of Media: -5 to 50℃

- Suitable Media: Corrosive fluid and gas, acid, alkali, etc

- Valve Material: PTFE

Features Of COVNA HKPF PTFE Solenoid Valves:

● With isolated diaphragm construction to rot-proof PTFE body for corrosion-resistant

● Suitable for acid, alkali, medical, and other mediums

● Widely used in the medical industry, medical industry and other applications

● Excellent anti-corrosion performance

● Responsive for flow control

Technical Parameters Of COVNA HKPF PTFE Solenoid Valves:

| Port size | 1/8″, 1/4″, 3/8″, 1/2″, 1″ | Orifice(mm) | 3, 6 |

| Port Thread | G, NPT | Function | Normally Closed |

| Pressure | 0 to 1.5 bar | Voltage | DC-12V, 24V; AC-24V, 120V, 240V/60Hz; 110V, 220V/50Hz |

| Temperature of Media | -5 to 80℃ (23℉ to 176℉) | Suitable Media | Corrosive fluid and gas, acid, alkali, etc |

| Material | PTFE | Tolerance | ±10% |

| Size | Port Size | Orifice(mm) | Cv | Min Pressure | Max Pressure | |

| AC(24VA) | DC(18W) | |||||

| HKFP2130 | 1/8″ | 3.0 | 0.1 | 0.0 MPa | 0.3 MPa | 0.3 MPa |

| AC(20VA) | DC(28W) | |||||

| HKFP2160 | 1/4″ | 6.0 | 0.28 | 0.0 MPa | 0.15 MPa | 0.15 MPa |

| HKFP2160 | 3/8″ | 6.0 | 0.28 | 0.0 MPa | 0.15 MPa | 0.15 MPa |

| HKFP2160 | 1/2″ | 6.0 | 0.28 | 0.0 MPa | 0.15 MPa | 0.15 MPa |

| HKFP2160 | 3/4″ | 6.0 | 0.28 | 0.0 MPa | 0.15 MPa | 0.15 MPa |

| HKFP2160 | 1″ | 6.0 | 0.28 | 0.0 MPa | 0.15 MPa | 0.15 MPa |

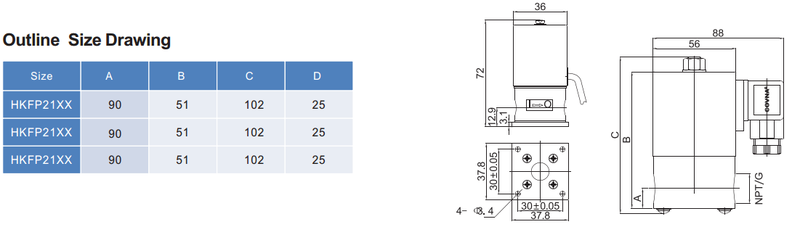

Dimension of COVNA HKPF PTFE Solenoid Valves:

| Port Size | 3/8”, 1/2″, 3/4″, 1″, 1¼”, 1½”, 2″ | Orifice(mm) | 15, 20, 25, 32, 40, 50 |

| Port Connection | BSPP,BSPT, NPT, Flange | Function | Normally closed or opened |

| Pressure | 0.00MPa-1.0MPa | Voltage | DC-12V, 24V, AC-24V, 120V, 240V/60Hz; 110V,220V/50Hz |

| Temperature of media | NBR Seal: 0~80℃

EPDM Seal: 5~190℃ |

Suitable Media | Alkali Acid and salt etc |

| Material | UPVC, CPVC | Sealing Material | EPDM, VITON,NBR, PTFE |

| Coil | YC1B , 15W ( AC ) , 16W ( DC ) | ||

| Coil | YELB, start at 200W, maitain at 5W(AC),28W(DC) | ||

| Coil | YF1B, start at 350W, maitain at 10W(AC), start at 75W,maitain at 25W(DC) | ||