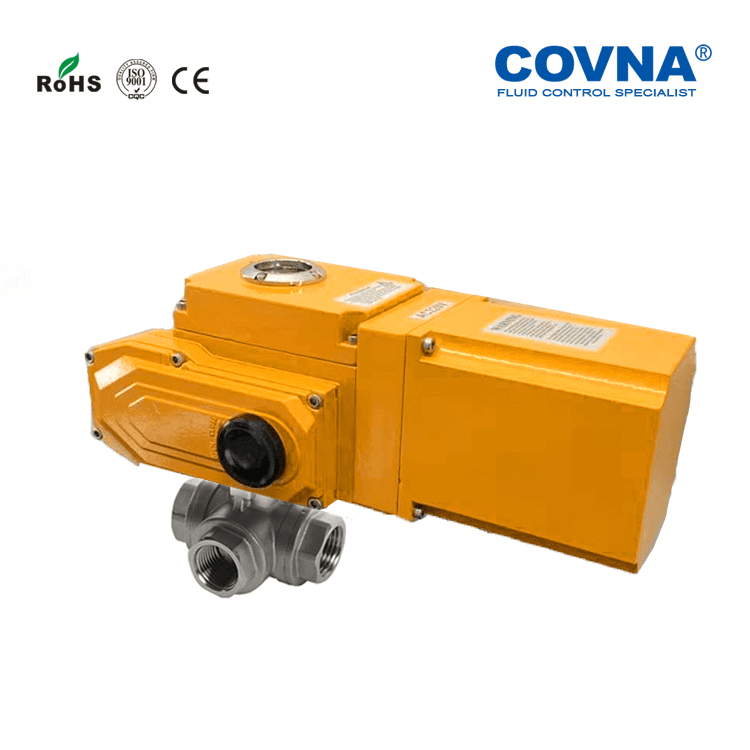

COVNA Fail-Safe Electric Actuator And Valve

Fail-Safe or Fail Open Electric Actuator

Driven by AC380V/220V/110V and 4-20mA signal to open or close the valve. Once the power off, the battery will drive the valve close. We provide fail-safe/fail-open actuators in quarter-turn types and explosion-proof types to meet your needs. Well for various industries like paper and pulp, oil and gas, irrigation, power plant, etc.

Model

- Type: Fail-Safe Type or Fail Open Type

- Shell Material: Aluminum Alloy

- Ambient Temperature: -25℃ to 65℃

- Protection Class: IP67

- Torque Range: 50Nm to 6000Nm

- Angle Of Rotation: 90 Degrees

- Voltage: AC-380V/220V/110V

COVNA Fail-Safe / Fail-Open Electric Actuator and it has a battery inside. Once the power off, the battery will be the power supply and drive the valve close or open. To keep your project safe and normal. ISO5211 mounting for ball valve and butterfly valve.

We will charge the battery when we test the actuator before shipment. Helping you save time.

Other Service of Fail-Safe / Fail Open Electric Actuator:

● Position Feedback: Features signal feedback to provide information on valve position and can also provide diagnostic information on the actuator and valve, such as degree of opening and closing and voltage readings.

● Remote Control: Fail-safe electric actuator valves can be controlled remotely, which allows for safe operation in hazardous or hard-to-reach areas. This can also help to reduce the risk of injury to operators.

● Explosion-Proof Design: Fail-safe electric actuator valves can be designed to be explosion-proof, making them suitable for use in hazardous environments such as chemical plants and refineries.

● Importance: By providing fail-safe operation, these valves ensure that critical processes can be safely and reliably controlled, even in the event of unexpected power loss or emergencies.

● Customizability: Fail-safe electric actuator valves can be customized to meet the specific requirements of an application, including the size and shape of the valve, the type of fail-safe mechanism used, and the materials used in construction.

Meanwhile, we could provide the whole set actuator valve for your choice! Like ball valve/butterfly valve with a fail-safe / fail-open electric actuator. To help you save the time of installation and commissioning.

Our goal is to help you select the right valve. Consult us to get a free valve solution!

Valve Types We Provide:

| Ball Valve Types | Butterfly Valves |

| ● Threaded Ball Valve | ● Wafer Butterfly Valve |

| ● Flanged Ball Valve | ● Lugged Butterfly Valve |

| ● Welded Ball Valve | ● Flanged Butterfly Valve |

| ● Tri-clamp Ball Valve(Food Safe Type) | ● Tri-clamp Butterfly Valve(Food Safe Type) |

| ● Wafer Type |

Meanwhile, we also provide valves in stainless steel, plastic, carbon steel and cast iron material for your options.

Packing:

Company Show:

Certificates:

1.Oil and Gas Industry

Pipeline Flow and Pressure Control: Used for flow and pressure control in natural gas and oil pipelines to ensure stability during transportation.

Gas and Liquid Distribution Systems: Regulates the flow of gases or liquids, ensuring precise control under various operating conditions.

Automation of Distribution Systems: Used in refineries and natural gas processing plants to automate fluid distribution and regulate the reaction processes.

2.Chemical and Petrochemical Industry

Reactor Pressure and Flow Control: Used in chemical reactors, storage tanks, and other equipment to control pressure and flow, ensuring stability in the chemical reaction process.

Flow/Pressure Regulation: Regulates the flow of liquids or gases in processes such as polymerization, refining, and distillation to ensure efficient production.

Steam Control: Regulates the flow and pressure of steam in steam generators and distribution systems.

3.Water and Wastewater Treatment

Water Flow Control: Regulates water flow and pressure in water supply and wastewater treatment systems to ensure normal operation.

Gas and Chemical Additions: Regulates the flow of chemicals or gases (such as chlorine or ammonia) added during the water treatment process.

4.HVAC (Heating, Ventilation, and Air Conditioning) Systems

Temperature Control and Airflow Regulation: Used in air conditioning systems to regulate the flow of cooling or heating fluids to maintain the desired temperature.

Pressure and Airflow Regulation: Adjusts the flow and pressure of air in ventilation, air conditioning, and humidification systems to ensure indoor comfort.

5.Food and Beverage Industry

Liquid Flow Control: Precisely controls the flow of liquids in processes such as brewing, dairy production, and beverage bottling.

Temperature and Pressure Regulation: Regulates temperature and pressure during heating, cooling, and sterilization to ensure product quality and safety.

6.Pharmaceutical Industry

Precision Flow Control: Regulates the flow of liquids and gases in pharmaceutical manufacturing processes to ensure precise control of process parameters.

Pressure Control: Adjusts pressure in cleaning and sterilization systems to ensure stable system operation.

7.HVAC Systems

Airflow and Temperature Control: Controls the flow and temperature of air to adjust environmental conditions, ensuring comfort and energy efficiency inside buildings.

8.Steel and Metallurgical Industry

Gas Flow Control: Precisely adjusts the flow of gases such as oxygen and nitrogen during smelting and heating processes to ensure stable furnace temperatures and chemical reactions.

Cooling Fluid Flow Regulation: Regulates the flow of cooling fluids in cooling systems to ensure temperature control of equipment.

9.Thermal and Power Industry

Steam and Water Flow and Pressure Control: Regulates the flow of steam and water in boiler systems, heat exchangers, and power plants to ensure efficient operation of thermal systems.

10.Mining Industry

Slurry Flow Regulation: Adjusts the flow and pressure of slurry during transportation and separation processes to ensure efficient extraction and processing of minerals.