COVNA utilizes the latest edition of SOLIDWORKS CAD and PRO/E system for valve design purposes. The system allows the Company to export drawings and datasheets to standard MS-Windows PC for an easy and accurate use by the various departments.

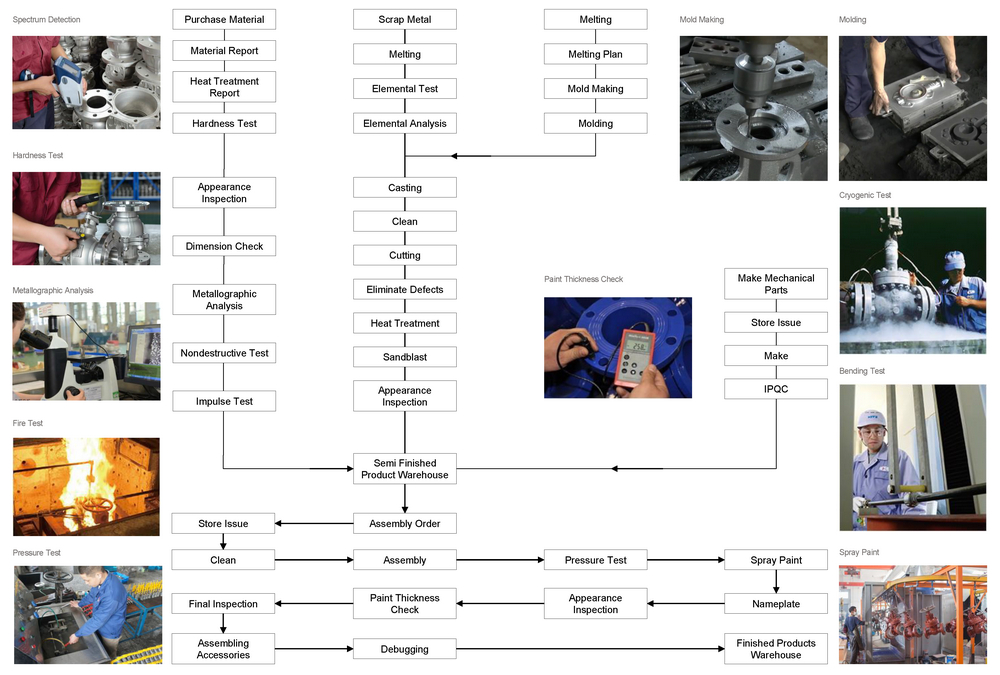

To produce the valve, it will generally undertake procedures below: scrap metal, melting, elemental test, casting, cleaning up, casting product inspection, machine processing, heat treatment, surface inspection, assembling, testing pressure, paint thickness check, finished product inspection, packed in polybag in carton, now that the valve can leave the factory.

See the whole PRODUCTION PROCESS below:

COVNA – Solve your technical questions with solid experience.

We are COVNA Automations, one of the top manufacturers of quarter turn actuators and automatic control valve products in Dongguan, China with 18 years experience. Our industrial experience will be useful in your business and projects.

PDF Get-a-Product Catalogue