COVNA Spring Return Pneumatic Actuator

Spring Return Pneumatic Actuator with rack and pinion system. Opens with pneumatic pressure and interrupts with closure. Air supply power between 2 bar and 8 bar. Torque output between 5.7Nm and 2792Nm.

COVNA is a manufacturer of spring return pneumatic actuators and double acting pneumatic actuators for an array of uses.

Select the suitable actuator with our assistance!

Model

Actuator Type: Pneumatic spring return

Air Supply Pressure: 2.5 to 8 bar

Construction: Aluminum alloy

Rotary movement: 0 to 90 degrees

Surrounding Temperature: -40 to 160 degree Celsius

Protection Class: IP65

Features of Spring Return Pneumatic Actuators:

- Spring return pneumatic actuator with feature of safe

- Rack and pinion pneumatic actuator with high output torque

- Easy to install and change the number of spring

- Weather-proof

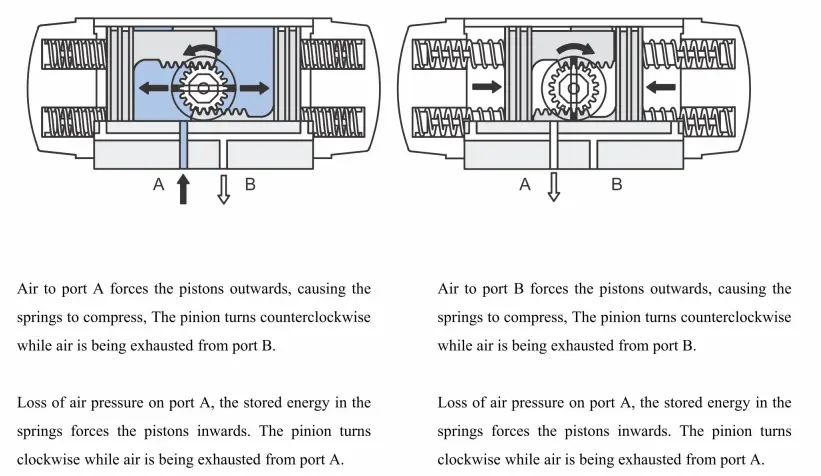

Working Principle Of Spring Return Pneumatic Actuators:

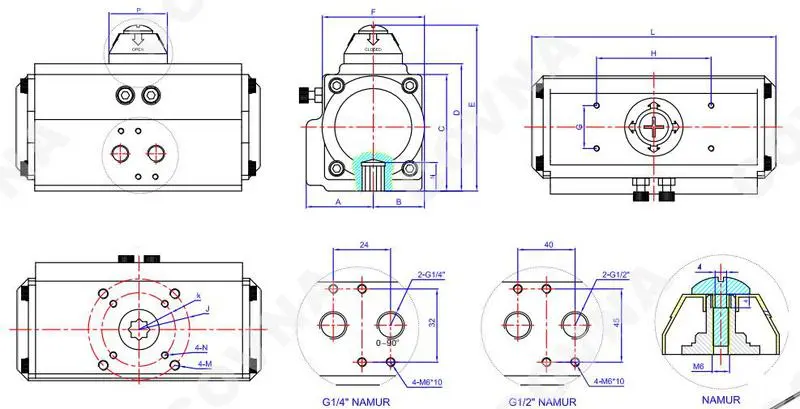

Dimension:

COVNA spring return pneumatic actuators are optimized for the following scenarios:

- Safety-critical systems: emergency shut-off of chemical/energy pipelines (spring automatically resets, valves safely close when power is off)

- Smart water treatment: pump station flow regulation (IP65 protection + aluminum body, anti-water mist corrosion)

- Food-grade production line: aseptic filling valve control (-40°C~160°C temperature resistance, in line with FDA hygiene standards)

- Packaging automation: high-speed opening and closing action (2-8 bar air pressure drive, precise 90° positioning)

- Fire protection system: sprinkler device fast response (2792Nm high torque, complete action cycle within 0.5 seconds)