COVNA Manual Gate Valve

Explore our extensive selection of knife gate valves, available in both electric and pneumatic configurations. These valves are specifically designed for handling highly concentrated or viscous media, offering reliable and efficient flow control solutions for a wide range of industrial applications.

What Is Knife Gate Valve?

A knife gate valve is a valve used to handle particles, or corrosive, viscous media, providing fully open and fully closed services. Easy to operate, simple design andsavespace.

The knife gate valve has stainless steel and corrosion-resistant knife, which can be effectively used in industries with corrosive media and can cut off impurities and is not easy to block. Long life span.

- Paper and pulp

- Power plant

- Chemical

- Cement plant

- Wastewater treatment

- and other applications

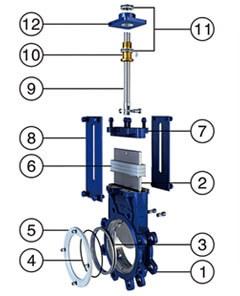

Material Table of Main Parts Of Knife Gate Valve:

| 1. Valve Body | 2. Gate |

| 3. Valve Seat | 4. O-ring |

| 5. Valve Seat Cover | 6. Packing |

| 7. Pacing Gland | 8. Brackte |

| 9. Valve Stem | 10. Valve Stem Nut |

| 11. Bearing | 12. Support |

Technical Parameter Of Electric Knife Gate Valve:

The valve body of the electric knife gate valve adopts an integral design, with low fluid resistance and flexible and convenient operation. The screw drive of the valve adopts a double-plane bearing design, which greatly reduces the transmission friction and facilitates the opening and closing of the valve.

| Actuator Type | Multi-turn Electric Actuator |

| Conventional Power Supply | Three-phase: AC380V |

| Input Signal | 4mA~20mA |

| Protection Class | IP65, IP68 |

| Size Range(Inch) | DN50 to DN2000 (2″ to 80″) |

| Pressure | 10 / 16 bar (145 / 232 psi) |

| Temperature | -10℃ to 400℃ (14°F to 752°F ) |

| Connection Options | Flanged or Lugged |

| Valve Material | Cast Iron or Stainless steel 304/316/316L |

| Seal Material | PTFE, Metal hard seal or hard alloy |

| Flanged Standard | ANSI B16.5, GB/T9113, JB/T79, HG, SH, JIS, DIN, NF, BS |

Technical Parameter Of Pneumatic Knife Gate Valve:

The pneumatic knife gate valve consists of a pneumatic actuator and a knife gate valve. The knife gate valve is light and flexible in operation, small in size, smooth in passage, small in flow resistance, light in weight, easy to install and easy to disassemble.

| Actuator Type | Pneumatic Cylinder (Double Acting or Single Acting Actuator) |

| Size Range(Inch) | DN50 to DN2000 (2″ to 80″) |

| Pressure | 10 / 16 bar (145 / 232 psi) |

| Temperature | -10℃ to 400℃ (14°F to 752°F ) |

| Connection Options | Flanged or Lugged |

| Valve Material | Cast Iron or Stainless steel 304/316/316L |

| Seal Material | PTFE, Metal hard seal or hard alloy |

| Flanged Standard | ANSI B16.5, GB/T9113, JB/T79, HG, SH, JIS, DIN, NF, BS |

Technical Parameter Of Knife Gate Valve:

COVNA knife gate valve with features of full bore design, low resistance and easy maintenance, two-way circulation, good wear resistance and soft seal and hard seal are optional

| Operated Type | Hand Wheel |

| Size Range(Inch) | DN50 to DN2000 (2″ to 80″) |

| Pressure | 10 / 16 bar (145 / 232 psi) |

| Temperature | -10℃ to 400℃ (14°F to 752°F ) |

| Connection Options | Flanged or Lugged |

| Valve Material | Cast Iron or Stainless steel 304/316/316L |

| Seal Material | PTFE, Metal hard seal or hard alloy |

| Flanged Standard | ANSI B16.5, GB/T9113, JB/T79, HG, SH, JIS, DIN, NF, BS |

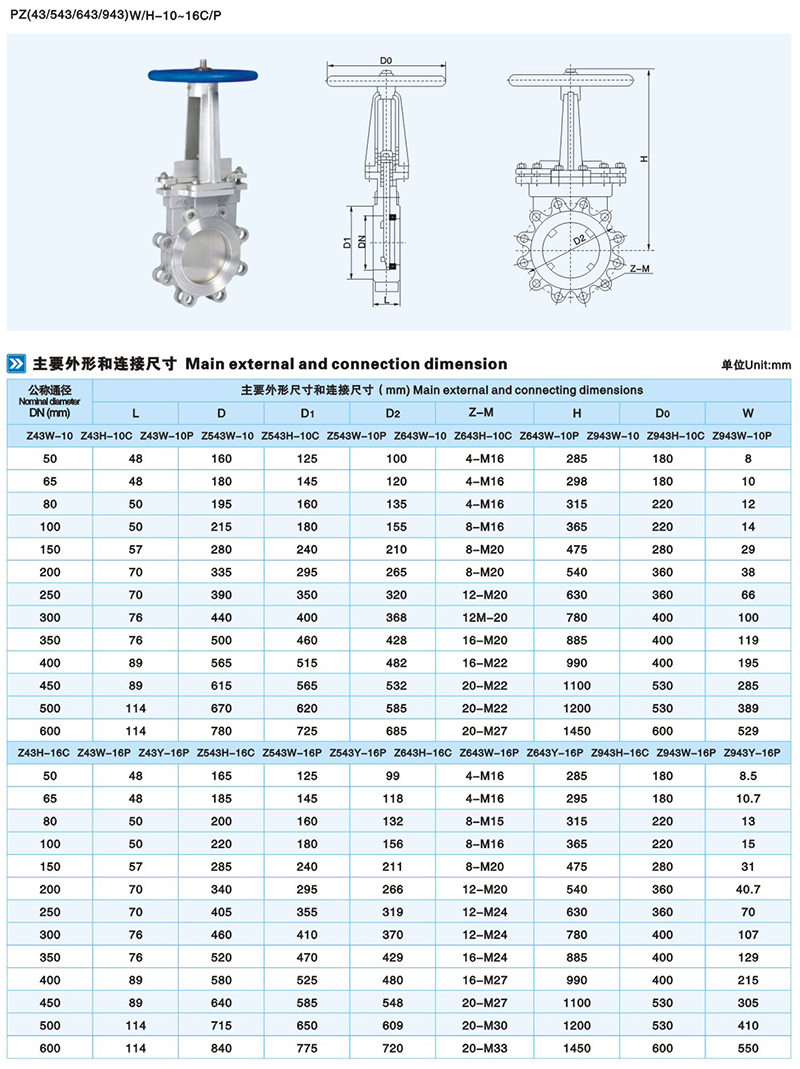

Dimension Of Knife Gate Valve:

1.Oil and Gas Industry

Pipeline Flow and Pressure Control: Used for flow and pressure control in natural gas and oil pipelines to ensure stability during transportation.

Gas and Liquid Distribution Systems: Regulates the flow of gases or liquids, ensuring precise control under various operating conditions.

Automation of Distribution Systems: Used in refineries and natural gas processing plants to automate fluid distribution and regulate the reaction processes.

2.Chemical and Petrochemical Industry

Reactor Pressure and Flow Control: Used in chemical reactors, storage tanks, and other equipment to control pressure and flow, ensuring stability in the chemical reaction process.

Flow/Pressure Regulation: Regulates the flow of liquids or gases in processes such as polymerization, refining, and distillation to ensure efficient production.

Steam Control: Regulates the flow and pressure of steam in steam generators and distribution systems.

3.Water and Wastewater Treatment

Water Flow Control: Regulates water flow and pressure in water supply and wastewater treatment systems to ensure normal operation.

Gas and Chemical Additions: Regulates the flow of chemicals or gases (such as chlorine or ammonia) added during the water treatment process.

4.HVAC (Heating, Ventilation, and Air Conditioning) Systems

Temperature Control and Airflow Regulation: Used in air conditioning systems to regulate the flow of cooling or heating fluids to maintain the desired temperature.

Pressure and Airflow Regulation: Adjusts the flow and pressure of air in ventilation, air conditioning, and humidification systems to ensure indoor comfort.

5.Food and Beverage Industry

Liquid Flow Control: Precisely controls the flow of liquids in processes such as brewing, dairy production, and beverage bottling.

Temperature and Pressure Regulation: Regulates temperature and pressure during heating, cooling, and sterilization to ensure product quality and safety.

6.Pharmaceutical Industry

Precision Flow Control: Regulates the flow of liquids and gases in pharmaceutical manufacturing processes to ensure precise control of process parameters.

Pressure Control: Adjusts pressure in cleaning and sterilization systems to ensure stable system operation.

7.HVAC Systems

Airflow and Temperature Control: Controls the flow and temperature of air to adjust environmental conditions, ensuring comfort and energy efficiency inside buildings.

8.Steel and Metallurgical Industry

Gas Flow Control: Precisely adjusts the flow of gases such as oxygen and nitrogen during smelting and heating processes to ensure stable furnace temperatures and chemical reactions.

Cooling Fluid Flow Regulation: Regulates the flow of cooling fluids in cooling systems to ensure temperature control of equipment.

9.Thermal and Power Industry

Steam and Water Flow and Pressure Control: Regulates the flow of steam and water in boiler systems, heat exchangers, and power plants to ensure efficient operation of thermal systems.

10.Mining Industry

Slurry Flow Regulation: Adjusts the flow and pressure of slurry during transportation and separation processes to ensure efficient extraction and processing of minerals.