COVNA AT56 Spring Return Pneumatic Actuator

Spring Return Pneumatic Actuator with rack and pinion construction. Air to open and interrupt to close. Air supply power range from 2 bar to 8 bar. Output range from 5.7Nm to 2792Nm.

COVNA manufactures pneumatic actuators in spring return and double-acting types for different actuation.

Consult us to help you choose the right actuator!

Model

Actuator Type: Spring Return

Air Supply Pressure: 2.5 bar to 8 bar

Material: Aluminum alloy

Angle Of Rotation : 0° to 90°

Ambient Temperature: -40 to 160℃

Protection Class: IP65

Features of Spring Return Pneumatic Actuators:

● Spring return pneumatic actuator with feature of safe

● Rack and pinion pneumatic actuator with high output torque

● Easy to install and change the number of spring

● Weather-proof

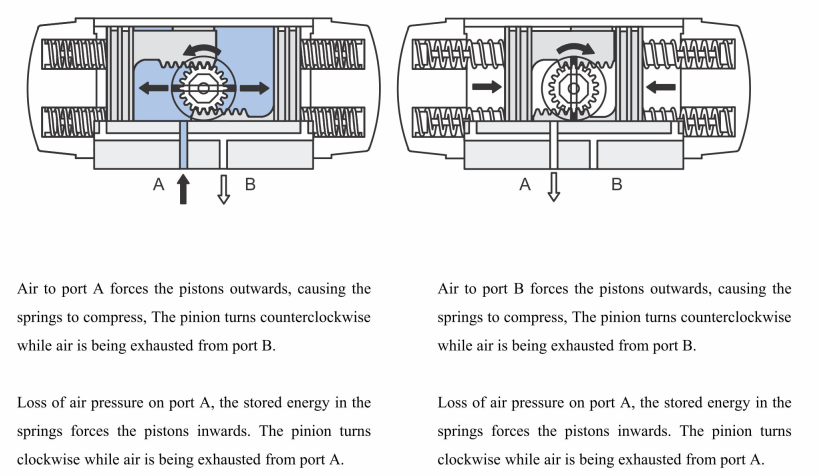

Working Principle Of Spring Return Pneumatic Actuators:

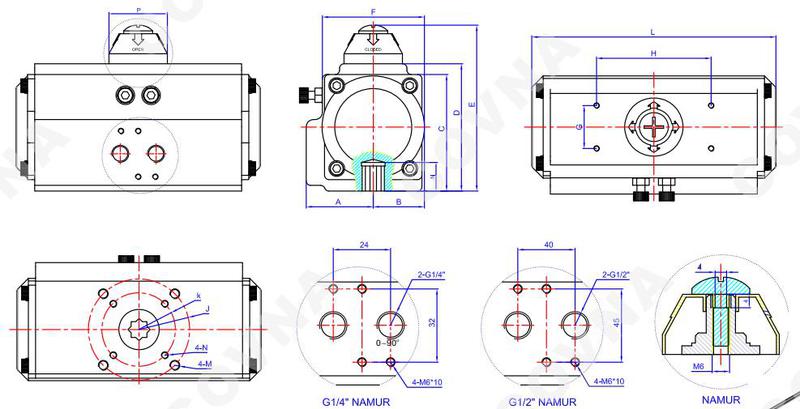

Dimension:

| Actuator Type | Double Acting |

|---|---|

| Pressure Range | 2 to 7bar |

| Temperature Range | 20°C to 80°C |

| Bottom Mounting Connection | ISO 5211/DIN 3337 |

| Rotation | 90° |

| Lifespan | 1,000,000 Times Rotation |

1.Oil and Gas Industry

Pipeline Flow and Pressure Control: Used for flow and pressure control in natural gas and oil pipelines to ensure stability during transportation.

Gas and Liquid Distribution Systems: Regulates the flow of gases or liquids, ensuring precise control under various operating conditions.

Automation of Distribution Systems: Used in refineries and natural gas processing plants to automate fluid distribution and regulate the reaction processes.

2.Chemical and Petrochemical Industry

Reactor Pressure and Flow Control: Used in chemical reactors, storage tanks, and other equipment to control pressure and flow, ensuring stability in the chemical reaction process.

Flow/Pressure Regulation: Regulates the flow of liquids or gases in processes such as polymerization, refining, and distillation to ensure efficient production.

Steam Control: Regulates the flow and pressure of steam in steam generators and distribution systems.

3.Water and Wastewater Treatment

Water Flow Control: Regulates water flow and pressure in water supply and wastewater treatment systems to ensure normal operation.

Gas and Chemical Additions: Regulates the flow of chemicals or gases (such as chlorine or ammonia) added during the water treatment process.

4.HVAC (Heating, Ventilation, and Air Conditioning) Systems

Temperature Control and Airflow Regulation: Used in air conditioning systems to regulate the flow of cooling or heating fluids to maintain the desired temperature.

Pressure and Airflow Regulation: Adjusts the flow and pressure of air in ventilation, air conditioning, and humidification systems to ensure indoor comfort.

5.Food and Beverage Industry

Liquid Flow Control: Precisely controls the flow of liquids in processes such as brewing, dairy production, and beverage bottling.

Temperature and Pressure Regulation: Regulates temperature and pressure during heating, cooling, and sterilization to ensure product quality and safety.

6.Pharmaceutical Industry

Precision Flow Control: Regulates the flow of liquids and gases in pharmaceutical manufacturing processes to ensure precise control of process parameters.

Pressure Control: Adjusts pressure in cleaning and sterilization systems to ensure stable system operation.

7.HVAC Systems

Airflow and Temperature Control: Controls the flow and temperature of air to adjust environmental conditions, ensuring comfort and energy efficiency inside buildings.

8.Steel and Metallurgical Industry

Gas Flow Control: Precisely adjusts the flow of gases such as oxygen and nitrogen during smelting and heating processes to ensure stable furnace temperatures and chemical reactions.

Cooling Fluid Flow Regulation: Regulates the flow of cooling fluids in cooling systems to ensure temperature control of equipment.

9.Thermal and Power Industry

Steam and Water Flow and Pressure Control: Regulates the flow of steam and water in boiler systems, heat exchangers, and power plants to ensure efficient operation of thermal systems.

10.Mining Industry

Slurry Flow Regulation: Adjusts the flow and pressure of slurry during transportation and separation processes to ensure efficient extraction and processing of minerals.