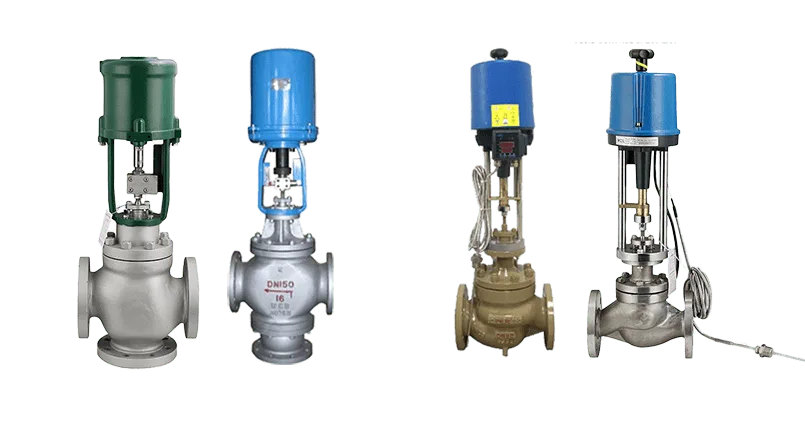

COVNA 3 Way Mixing Diverting Electric Globe Control Valve

3 way electric control valve has two action types: electric mixing(converging) control valve and electric diverting(diverging) control valve.The 3 way electric control valve is composed of PSL series and 3810 series linear electric actuator and 3-way valve body.The electric actuator is an electronic integrated structure with a servo amplifier. The input control signal (4-20mADC or 1-5VDC) and the power supply can control the valve opening to achieve to control the parameters of pressure, flow, liquid level and temperature. The electric 3-way mixing control valve is mainly used for mixing two fluids into a third fluid; the 3 way diverging electric control valve is mainly used for dividing one fluid into two fluids.

Model: Electric control valve

Size Range: 1” to 12”

Pressure Range: 1.6 to 6.4MPa

Material: Stainless Steel, WCB

Actuator Parameter:

| Model | Rated output power | Speed of mm/s | Technical parameters | ||||

| PSL | 361L | PSL | 361L | PSL | 361L | PSL | 361L |

| 201 | 361LSA-08 | 1000 | 800 800 | 0.25 | 4.2 4.2 | Power supply; AC220V 50HZ Input signal: DC4-20mA DC1-5V (shielding line signal line) output signal: DC4-20mA protection grade: IP67 With the handwheel | Power supply: AC220V 50Hz Input signal: DC4-20mA DC1-5V (shielding line signal line): DC4~20mA output signal Protection grade: IP65 Explosion proof mark Exdll With handle |

| 361LXA-08 | |||||||

| 202 | 361LSA-20 | 2000 | 2000 2000 | 0.5 | 2.1 2.1 | ||

| 361LXA-20 | |||||||

| 204 | 361LSA-30 | 4500 | 3000 3000 | 0.5 | 3.5 3.5 | ||

| 361LXA-30 | |||||||

| 208 | 361LSA-50 | 8000 | 5000 5000 | 1 | 1.7 1.7 | ||

| 361LXA-50 | |||||||

| 312 | 361LSC-65 | 12000 | 6500 | 0.6 | 2.8 | ||

| 320 | 361LSC-99 | 20000 | 10000 | 1 | 2 | ||

Valve Parameter:

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Seat diameter mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| Rated KV | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | 800 | 1280 |

| Nominal pressure (MPa) | 1.6,2.5,4.0,6.4 | |||||||||||

| Trip(mm) | 16 | 25 | 40 | 60 | 100 | |||||||

| With electric actuator model | 361LSA-20 | 361LSB-30 | 361LSB-50 | 361LSB-65 | 361LSB-99 | |||||||

| Input signal | 4-20mADC,1-5VDC | |||||||||||

| Power Supply | AC220V 50HZ | |||||||||||

| The inherent flow characteristics | Linear, equal percentage, quick opening | |||||||||||

| The inherent modulation ratio | 30:01:00 | |||||||||||

| The inherent modulation ratio | IV | |||||||||||

| Flange size | According to JB/79.1 (2) -94, HG20592-97, GB, ANSI, JIS, DIN and other standards | |||||||||||

| Body material | WCB, 304, 316, WC6, nickel, titanium, Hastelloy, Monel etc. | |||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||

| Working temperature ℃ | -40~230 | |||||||||||

| Series type | At room temperature, medium temperature type, bellows seal type | |||||||||||

The performance index:

| Project | Index value | ||

| The basic error % | With 361L±2.5;;With PSL±1.0 | ||

| Differential% | With 361L±2.0;;With PSL 1.0 | ||

| The dead zone % | With 361L±3.0; With PSL 1.0 | ||

| Always point bias % | Electric drive | The starting point | ±2.5 |

| Finish | ±2.5 | ||

| Power off | The starting point | ±2.5 | |

| Finish | ±2.5 | ||

| Adjustable range | 50: 1 | ||

| Rated stroke deviation% | 2.5 | ||

| Leakage | According to JB/T7387-94 IV less than the valve rated capacity of X10 -4 | ||

Dimensions and weight:

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | PN16 | 185 | 200 | 220 | 250 | 275 | 300 | 350 | 410 | 450 | 550 | 670 | 770 |

| PN40 | 190 | 210 | 230 | 255 | 285 | 310 | 355 | 425 | 460 | 560 | 740 | 803 | |

| PN64 | 200 | 200 | 240 | 265 | 295 | 320 | 370 | 440 | 475 | 570 | 752 | 819 | |

| H1 | 135 | 152 | 165 | 180 | 200 | 220 | 222 | 265 | 322 | 362 | 508 | 563 | |

| A | 225 | 310 | |||||||||||

| H Normal atmospheric temperature | 555 | 561 | 660 | 675 | 863 | 868 | 872 | 905 | 920 | 950 | 1203 | 1265 | |

| H Medium temperature | 707 | 709 | 812 | 827 | 1027 | 1032 | 1036 | 1120 | 1135 | 1165 | 1485 | 1557 | |

| Weight (PN64 Normal atmospheric temperature) | 50 | 55 | 70 | 78 | 110 | 120 | 150 | 180 | 310 | 410 | 650 | 810 | |

Types of Electric Control Valves: