Ball valves are widely used for their durability, strength and economy. Simple to install, they feature quarter-turn operation, making piping systems more efficient.

Although they are an easy choice for most applications, there are some disadvantages that you should be aware of when selecting the correct valve for your application. At COVNA Valve, the COVNA team responds quickly to customer needs, providing professional product selection guidance and reliable valve application solutions.

What is a ball valve.

Is cylindrical with a hollow pivot ball as the flow control element. When the ball is open, the hole through the ball faces the fluid, allowing the fluid to pass through. When the valve handle is turned 90 degrees, the ball closes and fluid flow through the valve stops. When the valve is open, the handle (or lever) is perpendicular to the direction of flow, providing an easy and visual indication of the valve’s status.

Advantages and disadvantages of ball valves

To help inform you when selecting the right valve for your application, we have listed the pros and cons of ball valves below:

Below we list the main advantages of using ball valves:

high efficiency

Ball valves are considered high recovery valves because of their low pressure drop and high flow due to the size of the opening on the ball. When the valve is fully open, fluid flows with little turbulence or resistance.

easy to use

Because of its simple quarter-turn (90-degree) operation, the ball valve is efficient and easy to use. Due to the relatively light weight and small size of the valve, installation and removal are also easy.

low maintenance

Compared with other types of valves, ball valves are simple in structure and require less maintenance. Since the ball stem rotates without axial movement, the packing seal on the stem is less prone to wear or failure. The ball valve is easy to disassemble and maintain, and the wearing parts are easy to replace.

Cost-effectiveness

The cost of ball valves is affordable when compared to more complex valve types. Additionally, due to their low maintenance requirements, they are less expensive to maintain and implement in the long run.

powerful

Ball valves are one of the strongest valve types because of their ability to withstand high pressures. Their wide range of materials enables them to be used in a variety of environments across a variety of industries.

The main disadvantages of ball valves are listed below:

easy to clog

They are not suitable for slurry applications due to the cavity around the ball and seat. Slurry or other viscous fluids tend to freeze or plug the interior of the valve cavity, causing a significant increase in operating torque and, in some cases, rendering the valve inoperable.

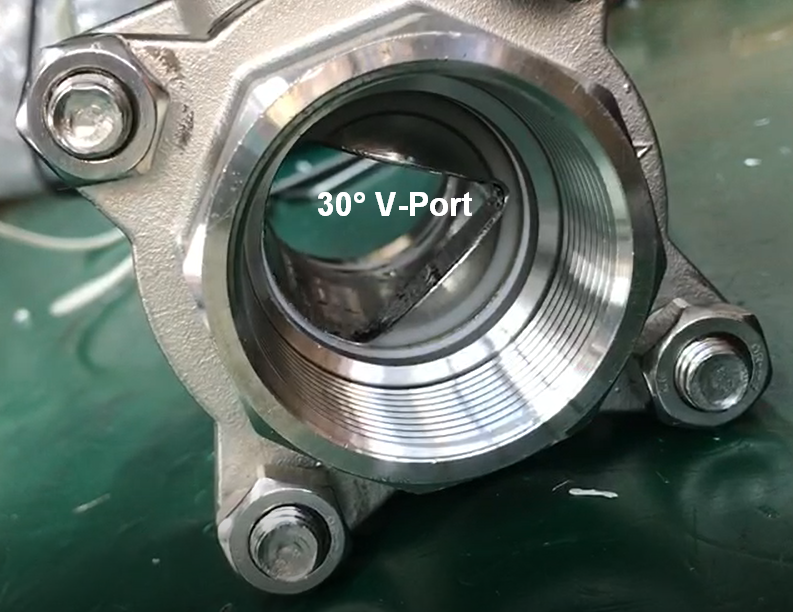

Combat chronic throttling

It can only be used in the fully open or fully closed position, and it is not suitable for long-term throttling. In addition to limited precision in controlling flow, prolonged operation in the partially open position can cause the soft seat of the valve to deform around the edge of the ball hole, potentially causing it to lock in that position. Modern design ball valves are equipped with special “V” shaped port balls that provide precise flow control characteristics.

summarize

It is a simple mechanical device used to control the flow of fluid through a piping system. Their cost-effectiveness and convenience make them ideal for most industrial applications. Their characteristics make ball valves ideal for a wide range of applications and environments.

PDF Get-a-Product Catalogue