HK60-Q-3PS 3-Piece Electric Actuator Ball Valve

Short Description:

HK60-Q-3PS 3-Piece Electric Actuated Ball Valve

with a torque range 50Nm to 4000Nm electric actuator which is available in on-off type, modulating type and intelligent type for your choice. Size range available in 1/2 inch, 3/4 inch, 1 inch, 1 1/4 inch, 1 1/2 inch, 2 inch, 2.5 inch, 3 inch and 4 inch. Voltage options: 12V, 24V-DC; 24V, 110V, 220V, 380V-AC. Suitable for water, oil, air, etc. Widely used in HVAC, irrigation, water treatment, paper and pulp and other projects.

As an electric actuator ball valve manufacturer, COVNA will help you choose the right electric actuator ball valve for your project and help your business grow.

Come and inquiry with us to select the best electric ball valve for your project!

Model

- Actuator Type: ON OFF Type, Modulating Type, Explosion-proof Type

- Body Material: Stainless Steel 304/316/316L

- Pressure: 10 / 16 / 25 /40 / 64 bar

- Temperature Of Media: 14℉ to 356℉

- Suitable Media: Water, Seawater, Fuel, Air, Oil, Gas, Steam, etc

- Voltage: DC-12V, 24V; AC-24V, 110V, 220V, 380V

- Connection Options: Thread/Welding/Flanged/Tri-clamp

What Is Electric Actuated 3-Piece Ball Valve?

Electric actuated 3-piece ball valve is a type of valve that uses an electric actuator to control the opening and closing of the valve. The 3-piece design of the valve refers to the construction of the valve body, which is made up of three separate pieces that can be easily disassembled for maintenance or repair. The ball valve itself consists of a spherical ball with a hole in the center that allows for the flow of fluid through the valve. When the electric actuator is activated, it rotates the ball within the valve body, either opening or closing the flow of fluid. Electric actuated 3-piece ball valves are commonly used in industrial applications where precise control of fluid flow is required, such as in chemical processing, oil and gas, and water treatment industries.

Benefits Of Electric 3-Piece Ball Valves:

COVNA electric 3-piece ball valves provide the most flexible fluid control solution. It can be customized as threaded connection, flange connection, clamp connection or welded connection to meet your various piping connection needs. Furthermore, the advantage of the 3-piece ball valve is that it is easy to disassemble, which will facilitate your routine valve maintenance and prolong the service life of the valve.

At the same time, the advantage of electric actuators is that they can receive and feedback signals to help you achieve remote control and regulate flow.

Features Of 3-Piece Electric Actuated Ball Valve:

- 3-piece ball valve design. Easy to maintain and repair to extend the lifespan

- 2 Versions of seals for choice: PTFE and PPL. To meet various mediums requirements

- Multi control methods for your choice: AC/DC power supply, signal control, Bluetooth control and manual override to help you control locally and remotely.

- Full port design with high flow rate feature

- Available in threaded, flanged, tri-clamp, and welding connections to meet your pipeline’s standard

- Available in normally closed type or normally open type

- Vast applications like water treatment, HVAC, paper & pulp, power plant, FGD industry, and other applications

Technical ParametersOf 3-Piece Electric Actuated Ball Valve:

| Body Material | Stainless Steel 304/316/316L | Working Pressure | 10 / 16 / 25 / 40 / 64 bar |

| Temperature Of Media | -10 to 180℃ (14℉ to 356℉) | Suitable Media | Water, Air, Oil, Gas, Pulp, etc |

| Structure | 2 Way 3-Piece ball valve | Voltage | DC-12V, 24V; AC-24V, 110V, 220V, 380V |

| Port size range | DN08 to DN100 | Voltage Tolerance | ±10% |

| Actuator Type | ON OFF Type, Modulating Type, Intelligent Type and Explosion-proof Type | Connections Options | Threaded/Flanged/Welding/Tri-clamp |

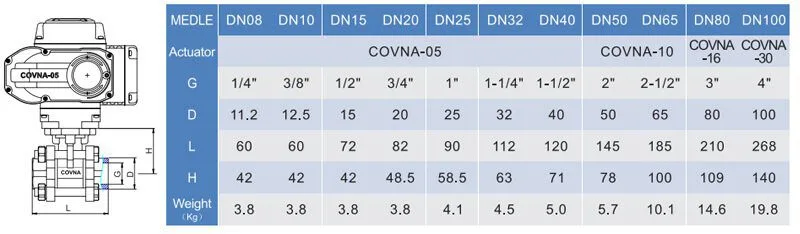

Dimension Of 3-Piece Electric Actuated Ball Valve:

Other COVNA Electric Actuator Options:

- Explosion-proof Electric Actuator: Exd II CT4 protection class to keep your project and personal safe. Torque range from 100Nm to 2,000Nm

- Auto Return Electric Actuator: In the event of a power failure, the battery drives the valve to reset. Suitable for use in the fire protection industry. Torque range from 100Nm to 6,000Nm

- Waterproof Electric Actuator: IP68 protection class and suitable use underwater. Like subsea exploration projects. Torque range from 50Nm to 2,000Nm

Technical Parameter Of COVNA Quarter-Turn Electric Actuator:

COVNA Quarter-Turn Electric Actuator uses a digital control system, which has the characteristics of high precision, fast response speed, and good stability, and can meet different industrial application requirements. In addition, the product also has multiple protection functions such as explosion-proof, waterproof, and dustproof, and can operate stably for a long time in harsh working environments

- ON/OFF Type Electric Actuator: For 90 degrees fully open and close.

- RegulationType Electric Actuator: For adjusting the switch angle from 0 degrees to 90 degrees.

- Intelligent Type Electric Actuator: For adjusting the switch angle from 0 degrees to 90 degrees with a display screen.

| ON/OFF Type | Feedback: the active contact signal, passive contact signal, resistance, 4-20mA |

| Regulation Type | Input & Output signal: DC 4-20mA, DC 0-10V, DC 1-5V |

| Field Operation | The field, remote control switch regulation and MODBUS, PROFIBUS field bus |

| Voltage optional | AC 110-240V 380V 50/60Hz; DC12V, DC24V, Special voltage can be customized |

| Protection Class | IP65 |

HK60-Q-3PS electric ball valve is widely used in the following scenarios due to its diversified configuration and high performance:

HVAC system

- Central air conditioning hot and cold water regulation

- Heating pipeline medium switching (water/steam)

- Intelligent building temperature control system (intelligent actuator)

Water treatment project

- Desalination plant high-pressure pipeline (64bar pressure resistance)

- Wastewater treatment plant reagent dosing system (316L corrosion resistance)

- Drinking water network remote control (DC12V low power consumption)

Industrial automation

- Petrochemical explosion-proof area (explosion-proof actuator)

- Paper mill pulp flow control (2.5″/3″ medium pipe diameter)

- Food grade medium transportation (Tri-clamp sanitary connection)

Energy infrastructure

- Natural gas distribution station (AC380V high-voltage drive)

- Power plant cooling water circulation (-10℃ low temperature environment)

- Biofuel production line (oil-resistant seal design)